Your organization grew from the desire to innovate products that improve human and animal health. DeJong Consulting partners with you to elevate your biotechnology operation’s processes to generate improvements that ensure your products are safe, effective, and meet regulations.

Just like you, innovation is at the core of our business.

We will sit down with you to talk through your organization’s accomplishments and vision. We’ll ask insightful questions and then get to work to find custom, creative plant design and process solutions for you. You will get unmatched customer service, a steadfast commitment to quality, and a goal to challenge our customers to think bigger. We work with businesses of all sizes and across industries to bring products to market more efficiently.

The foundation of science and technology is experimentation, improvement, and never settling for what’s familiar. Shouldn’t your biotech manufacturing process work the same way? DeJong Operations Management & Consulting LLC prioritizes flexibility and creative problem-solving, guaranteeing a system that fits your company’s aspirations.

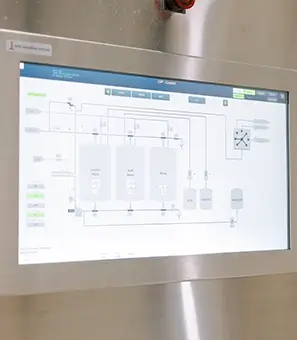

Our team works with you to identify process efficiencies, automation opportunities and equipment upgrades to help establish the long-term changes ahead for your organization. We are equipment-brand agnostic, flexible, and focused on creating the best possible version of your operation.

Our solutions include process consulting, plant design, project management, and equipment installation to support research and development, process piping, medical packaging, clean-in-place (CIP) systems, and more.

We strive to bring creative thinking and cross-industry experience to the table as we work to solve customers’ process and plant operations challenges. There is no challenge too complex for our team to solve and no business too big or small for us to partner with.

In the startup phase, an idea is generated, some market testing may be done, and the original product formulation is decided upon and tested in a contract manufacturing facility. It is key that this product be viable for commercial manufacturing. If required, we can also shepherd your product through product registration and regulatory compliance certification with the FDA, USP, USDA, or other governing bodies.

Once a viable product is decided on, is may be possible to engage a contract manufacturing facility to produce the product during the designing and building phases of your facility (sometimes this may be as much as a couple of years). This allows the company to focus on marketing and customer service while either bootstrapping the funds for a manufacturing facility, or using the proven product track record to raise funding. At DeJong, we often use contract manufacturing facilities to assist in formulating products and increasing production scale before we build a sanitary process line. If needed, we can assist in the selection, vetting, and validation of a contract manufacturing partner.

Once funding is secured through debt or equity, a pharmaceutical facility location can be purchased and built. This is generally the step where DeJong becomes heavily involved. From site selection to raw material handling and packaging, we build facilities that handle it all. For those who need a Turn-Key operation, we hire and train the staff before turning the facility over to the owner. The key is collaboration as we go through the process of designing procedures, manage available space, define flow for employees, and deal with HACCP plans for chemical or biological agents to develop critical safety systems to enable efficient, safe operations. It should be noted that speed is often among the most vital of benchmarks to achieve, given the constantly shifting marketplace that makes up biotech demand. We pride ourselves on decades of experience in this space, allowing us to react quickly and effectively as critical metrics inevitably shift throughout the project.

Have an existing facility that needs to expand? We often can increase production in an existing facility, or find the most affordable option for facility expansion.

The goal is an overall process that delivers a reliable product with high uptime and a low error rate. In a new facility design, the entire process is limited by the slowest step. In biotech engineering, we make better biology possible through heavy technological optimization.

From the moment the raw materials are delivered to the plant to the final shipping out of the product, we design a product line that eliminates product handling and reduces waste. Lean material handling techniques increases the productivity and revenue of a facility.

With a fully automated system, errors are reduced and employee costs are lowered, making it possible to affordable produce high-quality products here in the United States.

It all starts with a plant design that is engineered to handle bulk material while still being future-focused with the ability to expand in the long term.

We can take you from dirt to delivery and every bit of the process in-between.

When starting out, the most affordable solution is a contract manufacturer. The startup costs are lower, and the time to production is shorter.

We are often approached by companiess who desire to shift from a contract development and manufacturing organization (CDMO) to in-house production. Generally this desire is driven by supply chain issue or the need to scale beyond what the contract manufacturer is able to produce.

Additionally, we often consult on projects where the corporation has reached the current capacity limits of their manufacturing facility. They are seeking new ideas to increase production, add a new product line, or move to a larger facility. These are complex questions that our pharmaceutical engineers can easily provide guidance on.

Often production can be increased by improving a single, rate-limiting step. Our expertise enables us to quickly identify and provide recommendations for these areas of improvement.

Biotech and pharmaceutical companies often struggle with inefficient processes, regulatory complexity, outdated or inflexible plant designs, and manufacturing systems that cannot support scale, automation, or commercialization.

Many consultants lack true biotech experience, causing slow production, compliance risks, rate-limiting bottlenecks, and costly obstacles when transitioning from R&D to full-scale manufacturing.

DeJong Consulting delivers biotech-focused plant design, process engineering, and automation strategies that improve efficiency, ensure regulatory compliance, and support long-term scalability.

We partner closely with your team to redesign workflows, upgrade equipment, eliminate bottlenecks, integrate clean-in-place and automation technologies, and create future-ready facilities that reliably produce safe, consistent products. Our brand-agnostic, innovation-driven approach ensures your operation becomes the best version of itself — compliant, high-performing, and commercially viable.

Please complete the form to provide us with details about your project, and we’ll be in touch. Or you can call us at (715) 201-2772 , and our specialists will provide the necessary help!

DeJong Operations Management & Consulting LLC has a proven track record of helping clients from diverse industries maximize their return on investment and streamline their operations.