Improper pump selection can lead to surging issues, product waste, and early component wear. We are here to assist you in selecting the right pump that helps to reduce operating costs, minimizes downtime, and improves line efficiencies.

In food processing, a sanitary pump is a critical component. We can assist you in matching your specifications or provide a second opinion. With 15 years of experience, we have dealt with every pumping issue possible. Our services are available for both existing plants and new builds.

We offer a range of services, from pump supply to turn-key builds for new factories. We not only provide you with sanitary pumps but also act as a resource to solve problems as your business grows. Our contact number is the one plant managers keep in their personal cell phones.

Sanitary pumps, also known as hygienic pumps, are an incredibly important piece of equipment in the food, beverage, pharmaceutical, and personal care industries. They are specifically designed to meet strict sanitation standards while transferring liquids, semi-liquids, and suspensions without causing any contamination.

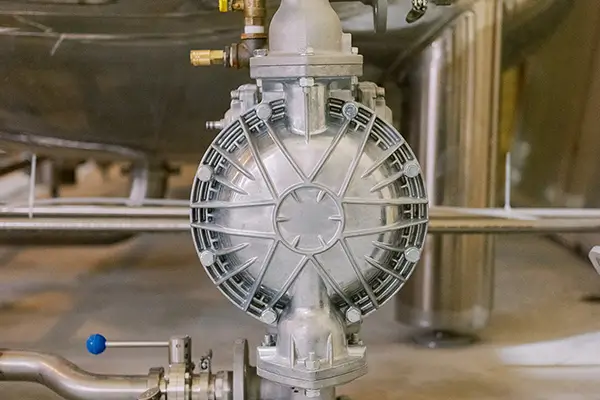

One of the key features of these pumps is their ability to leave no product residue behind after use. This helps to eliminate the risk of cross-contamination and ensure the highest levels of product quality and safety. Sanitary pumps come in a variety of types, including centrifugal, positive displacement, air-operated diaphragm, and magnetic drive pumps.

Centrifugal pumps are the most commonly used type of sanitary pump due to their versatility, efficiency, and basic design. They are capable of handling a wide range of fluids with varying viscosities and are often able to achieve high flow rates at relatively low pressures.

When it comes to the construction of sanitary pumps, high-grade stainless steel or other non-reactive materials such as copper are often used. The internal surface of these pumps is also crevice-free and polished to a mirror finish (a process known as electropolishing) to reduce the risk of bacterial growth.

The head is a measure of a pump’s power and refers to the maximum height it can raise a fluid against gravity. A higher pressure means a greater head achieved, which is important to consider when selecting the right sanitary pump for your production process.

Choosing the right sanitary pump is crucial for maintaining the highest levels of hygiene, safety, and efficiency in your production process. By understanding factors such as the viscosity and abrasiveness of the substance being pumped, you can select a pump that meets your specific requirements and upholds these important standards.

A sanitary pump is a type of pumping system that is specifically designed to process liquids or slurries while adhering to strict food safety standards. These pumps are commonly used in the food and beverage industry, where cleanliness and hygiene are of utmost importance.

Sanitary pumps can come in two types: ‘clean-in-place’ (CIPable) and ‘clean out of place’ (COPable). CIPable pumps are designed to be cleaned without disassembly, which means they can be easily cleaned by circulating a cleaning solution through the pump. This type of pump tends to be more expensive to manufacture and design, but it has lower long-term costs because it does not require additional man-hours to disassemble and reassemble during every cleaning cycle.

On the other hand, COPable pumps require disassembly to clean, which can be time-consuming and labor-intensive. However, they tend to be less expensive to manufacture and design, and they are generally suitable for smaller-scale operations.

Most styles of sanitary pumps are available in both CIPable and COPable configurations, which means that users can choose the type of pump that best suits their needs.

In summary, a sanitary pump is an essential component in ensuring food safety during liquid or slurry processing. It is important to choose the right type of pump depending on the needs of your operation to ensure efficient and cost-effective operations.

Below is a list of the most common types of sanitary pumps:

We also offer commonly used pumps in various industries, including dedicated hot water pumps.

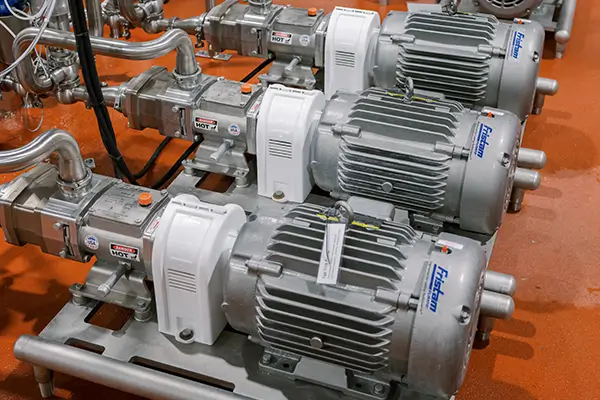

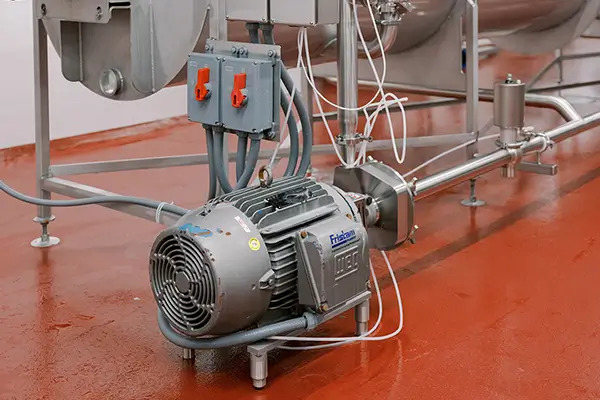

Centrifugal pumps are often preferred for their ability to maintain a high rate of flow using centrifugal force. They are especially useful for handling abrasive liquids. These pumps can handle a variety of products such as food, fluids, dairy/milk, and many others and are designed with an impeller that rotates within an enclosed casing. By utilizing centrifugal force, these pumps create suction, which propels fluids through a tube at high speed.

Centrifugal pumps are widely used in the food and beverage industry because they are cost-effective, offer high flow rates with minimal maintenance, and are suitable for pumping liquids with low to medium viscosity. They can handle a wide range of liquids, including water, milk, beer, and cough syrup, making them suitable for a variety of products. DeJong Operations Management & Consulting LLC has a sanitary pump selection that’s applicable in the dairy, food, beverage, pharmaceutical, and other sanitary industries. Sanitary pumps can cater to a viscosity of up to 200 centipoise (cp).

There are two types of centrifugal pumps: single-stage and multi-stage. Single-stage pumps have one impeller and are used for processes that require pumping at low pressure, such as transferring beer from a keg to the taps at a bar counter. On the other hand, multi-stage pumps use multiple impellers, depending on the number of stages involved, and are suitable for high-pressure applications, such as pumping water in high-rise buildings.

Impellers come in three types: open, semi-open, and closed. Choosing the right impeller depends on factors such as the material and viscosity of the liquid being pumped. Your pump comes with a new impeller, but it may need to be replaced from time to time.

Positive displacement pumps are ideal for processing high-viscosity fluids, thick liquids, or slurry materials, which are commonly found in the food industry. These pumps are typically either rotary or reciprocating in design. Rotary pumps use gears or cogs to turn and pump fluids, while reciprocating pumps use a back-and-forth suction motion to achieve the same result. Positive displacement pumps are particularly suitable for thicker and denser products.

In positive displacement (PD) pumps, the content is moved by trapping a certain amount and then forcing it into the discharge pipe after some time. These pumps provide a constant flow irrespective of the pressure, making them suitable for processes that require precise flow control. They use rotating gears or pistons to transfer the product at lower flow rates than centrifugal pumps, which means they can handle thick liquids like chocolate better.

Examples of positive displacement pumps include piston pumps, diaphragm pumps, rotary lobe pumps, peristaltic (hose) pumps, progressive cavity (PC) pumps, and gear pumps.

A liquid-ring pump is a type of rotating positive displacement pump that is commonly used as a vacuum pump in various industries such as chemical, electrical power, environmental, food and beverage processing, brewing, marine, mining, oil and gas, pharmaceutical, pulp and paper, and textiles. It has the advantage of handling flow and liquid products exceptionally well and can also deal with products that contain gas.

These pumps use water or other compatible liquids as the sealant and have no contacting parts, making them a safe and reliable option for handling dirty and potentially dangerous gas streams. Technically, it is a centrifugal pump, and the combination of a vacuum with a liquid seal makes it particularly useful for these industries. They are available in single and dual-stage designs and can also be configured as compressors for even greater versatility.

Using liquid ring pumps can help reduce production costs by saving on supply and reducing waste. It is a high-quality centrifugal pump that provides great returns.

What does it mean for a pump to be CIP-able? Essentially, it refers to a pump that is suitable for use in clean-in-place solutions. This means that you don’t have to disassemble the entire system of vessels, equipment, and pipework that come into contact with the product for cleaning purposes. A CIP system includes pre-rinsing, cleaning, final rinsing, and sterilization of a hygienic process. It can be done at temperatures up to 185ºF, using either acid or caustic detergents with numerous sanitizers.

CIP Systems can be either single-use, where the CIP fluid is wasted at the end of each use, or recovery-based, where the fluid is recycled for further use in subsequent cycles. With a CIP system, you don’t need to worry about spare parts or designing your system around hygienic standards. This saves you time and makes a CIP system a great option for a wide range of industries. It’s worth noting that not all sanitary pumps are CIP-compatible.

In traditional batch mixing processes, a lot of product waste can occur as the product tends to stick to the sides and bottom of the mixing tank. This can result in extended processing time waiting for the product to blend.

An alternative solution is using inline mixing and blending pumps, typically rotor pumps, which are ideal for thicker materials. These pumps create an effective, highly turbulent mixing zone by using high tip speeds and close clearances between surfaces. With inline powder mixing and blending pumps, all the product is passed through the rotor pump system before reaching the tank, resulting in a thoroughly mixed product in minimal time.

The energy exerted during inline mixing and blending is precisely and for a shorter amount of time than with in-tank mixing, which means that not only will you save time and energy on mixing and blending your product, but the pump is also fully CIP-able, allowing you to save time on cleaning while still meeting the most stringent sanitary standards.

Different rotor-stator options are available to accommodate a wide variety of specific mixing types, including blending, emulsifying, dispersing, dissolving, texturizing, and maceration (particle size reduction). However, it’s important to note that inline mixing and blending pumps are not a form of gentle product handling.

Peristaltic pumps, also known as hose pumps, tube pumps, or roller pumps, use an elastomeric hose at their core to fully contain the fluid and eliminate the possibility of product contamination. The hose’s external surface is not machined after extrusion, which enables better lubrication and reduces friction and heat buildup during operation. As a result, the hose lasts longer and requires less maintenance.

Peristaltic pumps are a flexible solution for a wide range of applications, including chemical processing, wastewater treatment, and food and beverage. They can transfer, dose, or meter various fluids, from low-viscosity liquids to shear-sensitive products, abrasive slurries, and materials suited for human consumption.

These pumps are particularly useful for pumping foods with off-gas, such as brewer’s yeast, due to their gentle motion. They also work well for pumping abrasive slurries like lime milk in mining applications or sodium hypochlorite at water treatment plants. When paired with variable speed drives or a PLC, the pump flow can be adjusted to accurately meter or dose fluids.

This type of pump is specifically designed for use in commercial applications where a constant and reliable supply of hot water is required. These pumps typically operate by using a combination of electric motors and hydraulics to draw water from a storage tank or other source and then distribute it throughout the building.

One of the key features of these pumps is their ability to maintain efficiency by providing a continuous flow of hot water on demand. Unlike traditional water heaters, which must constantly heat large volumes of water to maintain a steady temperature, these pumps only heat the water that is actually being used. This not only saves energy but also ensures that there is always a ready supply of hot water available.

Another important aspect of these pumps is their ability to prevent cold water lines from forming in the pipes. This is achieved by circulating the water in the pipes when the pump is not in use, which helps to ensure that the water temperature remains consistent throughout the system. This not only improves the overall efficiency of the system but also helps to prolong the life of the pump and other associated components.

Overall, these pumps are a reliable and efficient way to provide hot water in commercial settings and are an important part of many buildings’ plumbing systems.

The twin-screw pump is a highly efficient positive displacement pump that is designed to rotate with two screws, making it ideal for setups with low inlet pressure. It is a versatile pump that is perfect for processing a wide range of sensitive food products, such as processed cheese, peanut butter, meat, chocolate, whipped toppings, and more. Unlike other types of pumps, the twin-screw pump is better suited to handle these products, especially when the lines may only be partially full.

Twin-screw pumps are specifically designed to handle abrasive and high or low-viscosity fluids, making them ideal for use in hygienic applications in the dairy, food, beverage, and personal care industries. They operate quietly, with virtually no pulse, and their smooth and gentle operation makes them an excellent choice for handling sensitive products.

In addition to their superior pumping capabilities, twin-screw pumps are also capable of handling Cleaning-in-Place (CIP). Their low pulsation characteristics and excellent solids handling capability reduce the risk of product damage, thereby improving product quality. Maintenance is simplified, and process uptime is increased, making them a cost-effective solution for businesses in the food and beverage industry. Overall, twin-screw pumps are a reliable and efficient choice for businesses that require a high level of performance and reliability in their pumping operations.

A pump is considered sanitary when it is constructed using hygienic materials that are resistant to corrosion. Typically, stainless steel or high nickel alloy is used for this purpose. Additionally, it’s important that there are no areas in the pump chamber where the product can accumulate, known as ‘dead angles’. When a product requires high purity or is intended for human consumption, a sanitary pump is the appropriate choice.

A pump may be sanitary but not necessarily ‘clean-in-place’ or CIP-able, meaning you may have to clean it out of place by taking it apart and cleaning it separately – it cannot be left in place while a cleaning solution is run through it.

Meanwhile, a CIP-able pump is fully cleanable without disassembly. It remains in line during the cleaning process and does not require any disassembly to meet cleanliness requirements.

High-pressure pumps used in the sanitary industry are limited to a maximum pressure of 300 PSI. To enable easy cleaning and disassembly of pipes, Tri-clamps are used, which can only handle up to 140 PSI. Due to this limitation, sanitary plants are typically not built above 300 PSI.

It’s worth noting that there are no sanitary pumps available that are designed to achieve industrial high-pressure levels of 10,000 PSI, which are commonly used in the oil and gas industry.

Centrifugal pumps and positive displacement pumps are common types of pumps used in sanitary plants, but the application determines the pump style. Peristaltic pumps are also often used in high-purity pharma designs. In pharmaceutical processing, these pumps commonly handle critical process fluids to ensure the best possible cleaning standards. However, this level of cleanliness is not always necessary in food processing. The type of product being handled determines the appropriate pump to be used.

Sanitary pumps are the ideal choice for food and beverage processing applications due to their numerous benefits.

The pump must be certified as American 3A or EHEDG (European standards) and also pass FDA standards. This is in line with the requirements for a pump to be considered sanitary.

Without a doubt, a sanitary pump is the lifeline of your food processing line and plays a vital role in ensuring the quality and safety of your products. As your trusted partner, we understand the importance of selecting the right pump that meets your specific requirements and industry standards. With 15 years of experience, we have encountered and solved every pumping issue imaginable, making us the experts in the field.

Whether you are building a new plant or upgrading an existing one, we are here to help. We offer a wide range of services, from pump supply to turnkey builds of new factories, and we are committed to providing you with exceptional service and support at every stage of your project.

We go beyond just supplying your sanitary pumps. As your reliable industry resource, we are always available to provide a second opinion and help you solve any problems that may arise as your company grows. We take pride in being the go-to phone number that plant managers keep in their personal cell phones.

So, if you want to ensure the smooth and efficient operation of your food processing line, look no further. Contact us today, and let’s discuss how we can help you achieve your goals.

DeJong Operations Management & Consulting LLC has a proven track record of helping clients from diverse industries maximize their return on investment and streamline their operations.