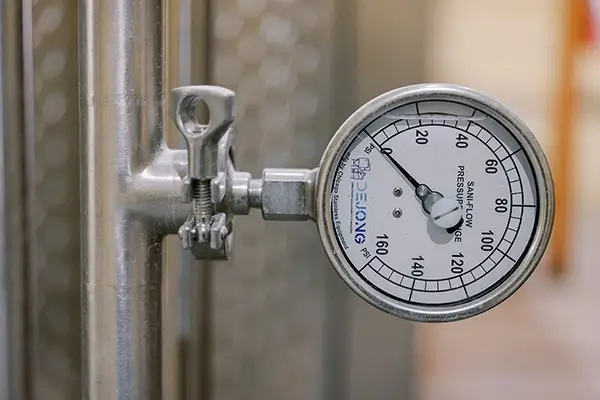

In the beverage industry, hygiene, quality, and efficiency are non-negotiable. At the core of DeJong Consulting’s operations lies a steadfast commitment to ensuring impeccable standards in every aspect of production.

Effective cleaning practices are the cornerstone of sanitation and quality control in facilities. By prioritizing cleanliness, we not only enhance uptime and operational efficiency but also safeguard against contamination, ensuring that every product meets our stringent quality standards.

Throughout the entire beverage production process, sanitation remains a constant focus. From cleaning to CIP (Clean-in-Place) procedures, every step is meticulously executed to uphold the taste and overall quality of your beverages. Sanitization plays a pivotal role in eliminating bacterial contamination, ensuring that your products exceed expectations and deliver unparalleled freshness with every sip.

In essence, sanitation is the difference-maker that propels us to go that extra mile. By maintaining rigorous cleaning standards and implementing robust sanitization protocols, we uphold our commitment to safety, efficacy, and cleanliness in every aspect of the beverage production process.

Maintaining impeccable hygiene standards in beverage plants is paramount to ensuring product quality and consumer safety. However, several challenges pose significant obstacles to achieving this goal. At DeJong Consulting, we offer comprehensive solutions to overcome these challenges and optimize sanitation processes in beverage plants.

Product contamination, particularly by bacteria such as E. coli and Listeria, poses a severe risk to both consumer health and brand reputation. To mitigate this risk, our team implements stringent hygiene protocols and sanitation measures throughout the production process. By prioritizing cleanliness and adherence to food safety standards, we safeguard against potential contamination issues and uphold product integrity.

Establishing ongoing training programs and clear procedures is essential for ensuring that employees understand and adhere to sanitation protocols. At DeJong, we emphasize the importance of proper training and communication to promote a culture of hygiene and safety in beverage plants. By equipping employees with the knowledge and skills necessary to perform their roles effectively, we enhance overall sanitation practices and minimize the risk of human error.

Understanding the various types of contamination—such as cross-contamination, microbial contamination, and particle contamination—is crucial for implementing targeted sanitation strategies. Our team conducts thorough assessments to identify potential sources of contamination and develops customized solutions to address each specific challenge. From employee hygiene practices to equipment sanitation, we leave no stone unturned in our quest to maintain pristine production environments.

Cross Contamination

Cross-contamination is a common problem that occurs when manufacturing plants use different ingredients to produce their products. It often happens due to mishandling of ingredients by employees or inadequate cleaning of the production equipment. The most frequent cause of cross-contamination is when one process line is being cleaned while another process line is still producing goods, leading to recalls and other issues.

Microbial Contamination

Contamination can occur when bacteria are introduced into a product. This may happen due to poor hygiene practices by workers, such as not washing their hands or not wearing protective gear. It is important to prevent bacterial contamination as harmful bacteria can spread quickly in products, potentially causing foodborne illnesses and threatening the well-being of consumers. In addition to poor hygiene practices, cleaning fluids or condensate dripping from ceilings and mechanical lines can also introduce bacterial loads into products.

Particle Contamination

Contamination of beverages can occur when debris or dust enters during production or packaging. This can happen due to insufficient sanitization methods and poor air filtration. In some cases, the HVAC system plays a critical role in the manufacturing process, to the extent of determining the facility and its location. Proper attention should be given to the size of filtration and air movement to achieve an effective reduction in particulate matter.

Our approach to sanitation encompasses a holistic system of integrated cleaning procedures tailored to the unique needs of beverage plants. Whether through Clean-In-Place (CIP) or Clean-Out-of-Place (COP) methods, we ensure that equipment and facilities are thoroughly cleaned and sanitized to industry standards. By optimizing factors such as time, chemical usage, and equipment programming, we maximize cleaning efficiency while minimizing environmental impact.

Standard Operating Procedures (SOPs) are guidelines that assist in maintaining consistent and effective sanitation practices. We collaborate closely with beverage plant operators to create unambiguous SOPs that simplify cleaning procedures and meet regulatory standards. Furthermore, we offer extensive training programs to enable employees with the necessary expertise and abilities to execute SOPs with precision and consistency.

Establishing a consistent cleaning schedule is crucial to maintain hygiene standards and promote productivity in beverage processing plants. Our team works with clients to develop personalized cleaning schedules that prioritize efficiency and effectiveness. By implementing regular validation and sanitization procedures, we ensure that the highest standards of cleanliness and food safety are always upheld.

Automated Clean-In-Place (CIP) systems provide a convenient and efficient way to clean beverage processing equipment without having to take it apart. Our automated CIP systems use advanced technology to ensure a thorough cleaning and sanitization process while reducing downtime and the risk of human error. Every stage of the cleaning process, from pre-rinsing to sanitizing, is carefully executed to achieve the best results.

Ensuring the safety of our plant employees is our top priority, as it creates a secure working environment. The DeJong Consulting team conducts hazard analyses and implements preventive measures to ensure that the employees are protected from any potential harm while working. This includes providing them with appropriate Personal Protective Equipment (PPE) that is cut-resistant and can withstand high temperatures. By equipping your employees with such PPE, we mitigate the risk of injuries and promote a culture of safety in your beverage plants.

At DeJong Consulting, we are dedicated to addressing the complex challenges of beverage sanitation with innovative solutions and industry expertise. By combining cutting-edge technology with rigorous sanitation protocols, we empower beverage plants to maintain the highest standards of hygiene, quality, and efficiency. No challenge is too complex for our team to tackle, and we remain committed to partnering with businesses of all sizes to achieve their sanitation goals.

Our team of specialists looks forward to working with you! Get a quote

Please complete the form to provide us with details about your project, and we’ll be in touch. Or you can call us at (715) 201-2772 , and our specialists will provide the necessary help!

DeJong Operations Management & Consulting LLC has a proven track record of helping clients from diverse industries maximize their return on investment and streamline their operations.